Friday May 09, 2014

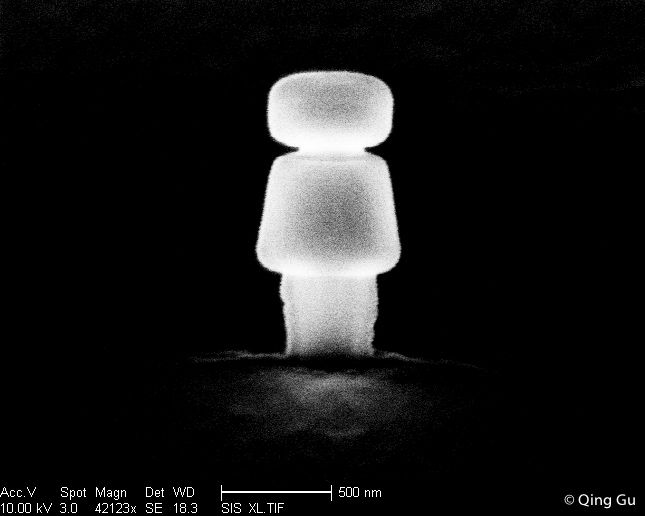

It resembles a mushroom cloud, but in fact, it’s one of our microscopic nanolasers, imaged under an electron microscope. These lasers are among the smallest in the world, so small you could fit a billion of them on an iPhone home button, small enough to one day fit easily on a computer chip to help computers send data using light.

Here, you see the laser partway through our fabrication process, a process that can take a week or more. In the previous step, the laser was coated with a puffy layer of glassy material, used to keep the laser light from leaking away and to keep the laser’s two electrical contacts separated. At the center beneath this smooth white layer lies the actual laser core. When my labmate Qing gets to this step, it comes with a sense of relief, since the glassy layer helps strengthen the laser, keeping it from snapping in half. When this laser’s eventually finished, it will be encapsulated in a thin shell of metal, and emit light through its base.